About Us

Welcome to the forefront of wood drying technology in North America, where expertise meets innovation. As experts in the design and development of wood-drying kilns, we take immense pride in crafting cutting-edge solutions that redefine industries and enhance the quality of kiln-dried wood. Our commitment translates into tangible results: enriched cash flow for all our esteemed clients.

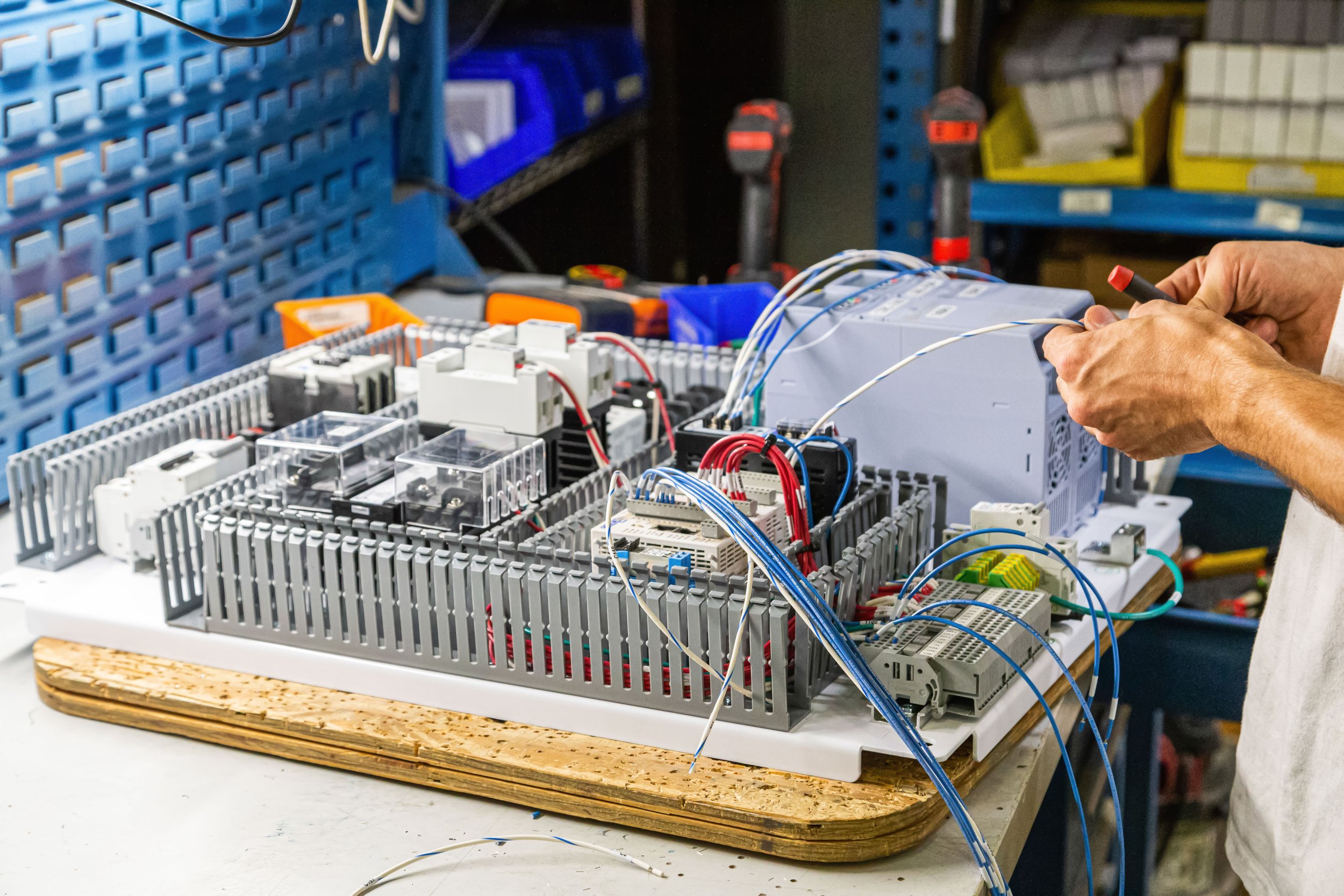

All our kilns, their software, and touch-screen controls are produced from scratch in our manufacturing facility in Barre, Vermont. Completely made in the USA, raw materials come in one end of the building and beautiful shiny kilns go out the other.

At iDRY, we are dedicated to working closely with each customer, developing new processes and opportunities for increased profitability. Any sized sawmill, furniture design, or wood business will be at an advantage when using an iDRY kiln because the results you get are unmatched in color, flatness, and stability. Not only that, our kiln technology delivers up to a 20% increase in yield and up to a 40% increase in throughput of your dried wood.

iDRY vacuum kiln technology is already accomplishing what so many said was impossible. As we look forward, we embrace the challenges, opportunities, and rewards of being on the cutting edge. Join us.

Superior Efficiency. Every Kiln Load. Every Time.

All iDRY models promise the same fast, reliable, and efficient drying results by using a combination of heat and vacuum. The iDRY Turbo dries lumber and squares from 4/4 to 16/4 ten times faster than conventional kilns, while the iDRY Standard and iDRY PLUS dry about five times faster.

The Benefits of an iDRY Kiln System. What’s in it for you?

Drying wood 5-10 times faster means you sell your wooden slabs and wood products 5-10 times faster, which puts money in your pocket 5-10…actually 10.5 times faster…which means, well, you get it.

Think of the time you save. What if you could turn a log into flooring and sell it in a week? An iDRY Turbo with the capacity of 6000 board feet will dry close to 1 million board feet of 4/4 hard maple in a year.

Grow or Start a wood drying business with an iDRY Kiln and see how far it can take you.

Speed doesn’t cost more

iDRY gives you an energy cost of pennies per board foot. Low electricity demand and very low and efficient use of heat energy means you dry faster with a smaller boiler and minimal electricity. Think home heating system size boiler and clothes drier size electrical demand!

About Vacuum Drying

How it works?

The Vacuum Dryer utilizes a vacuum to lower the temperature at which water boils (evaporates). Wood is stronger at a lower temperature. By drying at a low temperature we can accelerate the drying time without harming wood. Vacuum pressure also sucks the water from the core to the shell, which is particularly handy for thicker dimensions.

Why you should care?

Drying fast increases throughput, inventory turnover and cash-flow. Drying fast with excellent color and very little degrade improves the value of your product. Drying Lumber FLAT increases yield. Yield = $$$

Vacuum Kiln Information

For the Casual Glancers

All iDRY kilns utilizes a continuous vacuum to dry, while heating with aluminum hot water heating plates or circulated hot air. This dries wood up to 10 times faster than conventional methods, and the added benefit of the rubber bladder press (iDRY Turbo only) has made it possible to keep the lumber flatter and straighter than ever before.

For the Wood Drying Super Geeks (ourselves included)

All iDRY kilns use a vacuum to create a pressure gradient between the shell and the core of the wood. Conventional drying methods rely on moisture differential or gradient to move the water from the wetter core toward the dryer shell. This can be a slow process since the operator must be careful not to over dry the shell or degrade will result. The iDRY achieves its fast drying rates by maintaining a small differential between the shell and the core moisture contents throughout the drying period. Typically, the core of the wood is essentially at atmospheric pressure, while the shell of the wood is at a much reduced pressure, causing the water to flow toward the shell more rapidly.

When drying lumber it is necessary to increase the temperature while maintaining a vacuum. This causes the environment within the dryer to become superheated and therefore the equilibrium moisture content is reduced causing the moisture from the wood to convert to water vapor at the reduced pressure. The moisture from the wood can then be condensed and removed from the pressure vessel and drained via the floor drain or vacuum pump.

We cannot believe anyone has read this far. The guy who wrote this didn’t even read this far…

Now on to the rubber bladder. The iDRY Turbo rubber bladder press which is placed on top of the lumber pile, then inflates on top of the lumber and presses against the kiln ceiling during the drying process.

The pressure applied to the top of the lumber can be as high as 1,600 pounds per square foot and is maintained even while the lumber is cooling after the final moisture content has been achieved. The result is very flat and straight lumber, free from cup, twist and bow.

Heating the lumber is necessary to circulate water within the wood and bring it to the surface so that it can be evaporated as steam, which either condenses on the cool walls of the pressure chamber and runs to drain or is drawn out of the pressure chamber by the vacuum pump as steam. iDRY Turbo kilns use aluminum heating plates, which are heated by hot water that is circulated within the plate (not unlike a radiator).

Wow if you’ve read this far leave now… your family misses you.

The iDRY system is very effective at heating the wood without damaging or darkening it due to the low pressure(vacuum) environment, in fact the low oxygen environment actually contributes to the bright colors that result from the vacuum drying process. Hot water heating plates are also a very economical method of heating the wood, because the water can be heated by almost any boiler system (i.e. Wood Waste, Gas, Propane, Oil or Electric).

As water is removed from the wood by both the forces of heating and vacuum, the water either remains on the surface of the wood to humidify and condition the surface against over drying or it is evaporated as steam, which occurs during the drying phases of the schedule. A schedule of drying and conditioning the wood is used to relieve internal and external stress in the wood through the process. This is especially important for woods such as Red Oak or other difficult to dry species.

You finished it. You know more about iDRY than any of your family, friends and competitors. Your business may never be the same again…